Ahmedabad’s Most Reliable Pillar Drill Machine Manufacturer, Supplier & Exporter

A pillar drill machine is a high-power, precision drilling machine that is mounted on a solid column (pillar), used to create accurate and efficient holes in many different materials. Our Pillar Drill Machine Manufacturer at SK Industries are designed to be precise, powerful, and durable for work in industrial setups. Its long-lasting construction and massive drilling force put it into zones of preference in workshops, manufacturing units, and heavy engineering industries.

The unique feature of our pillar drill machines is the user-oriented design coupled with solid mechanical engineering. Our machines are loaded with options such as adjustable drilling heads, variable speeds, and heavy-duty work tables to give them the flexibility and the productivity needed in any machine shop, fabrication unit, or even a maintenance workshop. Single-component drilling or batch processing, SK Industries provides machinery that will drill with accuracy, each and every time.

What is a Pillar Drill Machine?

A pillar drill machine is a drilling machine mounted on a stationary vertical column (pillar) to support the drill head and table. Pillar drills are also essential in workshops, factories, and industrial use because they, unlike hand drills, are accurate, stable, and consistent in their results.

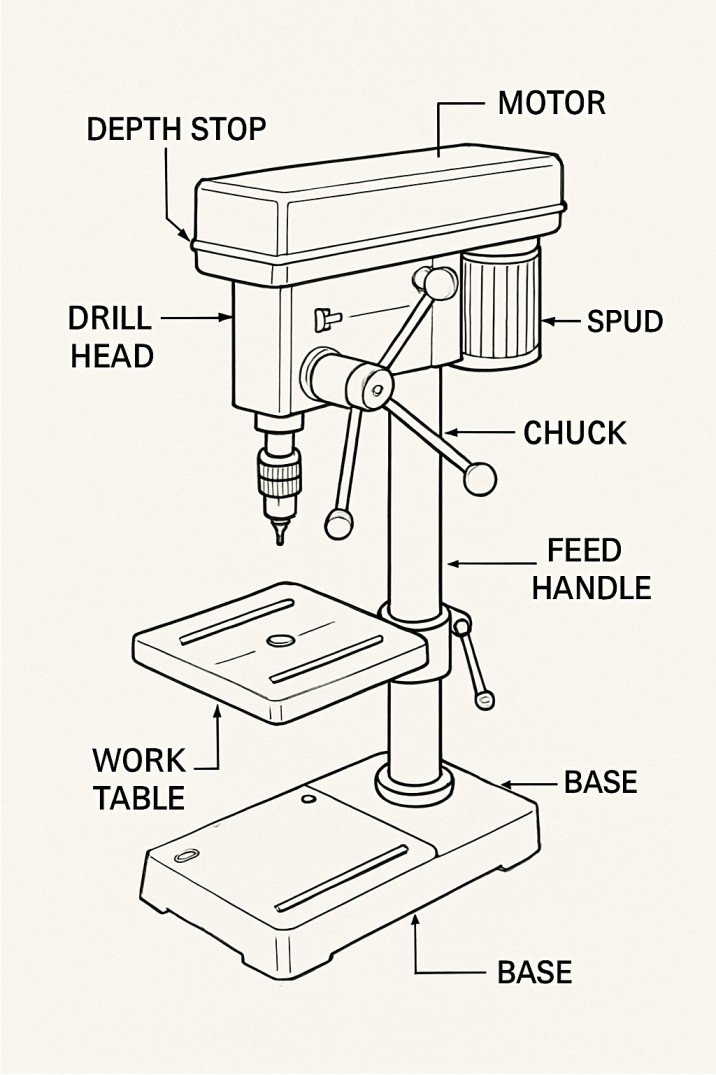

Key Components:

Column/Pillar: Supplies vertical loading of the drill head.

Drill Head: The motor and the spindle are housed.

Worktable: A Portable platform to fix the piece of work.

Base: Foundation to be stable.

Feed Mechanism: Drill movement is controlled to be precise.

Spindle & Chuck: Rotates drill bits.

Whether it is a bench drilling machine or a pillar drilling machine, a 40mm pillar drilling machine, a 20mm capacity heavy-duty drill machine, or all other products of SK Industries are created with the finest CNC technologies, premium quality components, and stringent quality controls. Our designs and processes are continually being upgraded to meet international standards, and customers get advanced features like energy-efficient motors, low maintenance requirements, and safer operators.

How to Use Safely

- Always secure the material to the work table.

- Position the appropriate speed of material drilling.

- Use a depth stop to ensure consistent hole depth.

- Use eye protection and avoid hand-on bit.

- Read and observe the user manual prior to use.

At S.K. Industries, we manufacture all types of drill machines that meet both industrial and workshop requirements with unmatched performance and longevity. You get a reliable partner for all your drilling solutions—delivering performance that lasts.

Key Features

High Drilling Power

You will be able to obtain the models with a drilling capacity of 20 mm to 40 mm, and they can be applied in both light-duty and heavy-duty operations.

Variable Speed

Most pillar drill machines are variable speed (up to 8 speeds) with RPM typically 80-3500, which may be adjusted to perfectly suit the material and size of drill bits in use.

Robust Design

It is designed with a solid column (pillar), base, which makes its usage vibration-free and ensures prolonged usage. An example is that heavy-duty types can have a column diameter of up to 115 mm with a base of 660 mm x 420 mm.

Flexible Table

The machine is most likely to possess a tilting or cast working table that enables drilling at angles, and it is also much more flexible when performing complex operations.

Precision Engineering

High drilling precision, as defined in the IS standards, is ensured through precision feed and hardened gears, precise spindle alignment, etc.

High Motor

Comes standard with a 1 HP electric motor, delivering consistent torque during tough applications.

Applications

- Metalworking: It used to drill, ream, and tap in steel, cast iron, and non-ferrous metals.

- Woodworking: Suitable for drilling precise holes in hardwoods as well as engineered wood products.

- Plastic and Composite Materials: Ensures clean, precise holes in a wide range of synthetic materials.

- Industrial Fabrication: Used in automotive, aerospace, construction, and general manufacturing industries.

Benefits

- Precision: Each time it is drilled correctly

- Stability: A Heavy base will minimize vibration.

- Versatility: Drills wood, metal, plastics, and composites

- Durability: It is intended to be used long-term in an industry

- Safety: Stationary structure lowers operational risks

- Efficiency: Flexible speeds of various materials and needs

What is the Best Way to Select the Right Pillar Drill Machine?

Before buying, consider the following:

Drilling Capacity: The largest diameter that a hole can be drilled.

Motor Power: Defines the efficiency of drilling hard materials.

Speed Control: Variable RPM of various materials.

Worktable Size: Accepts larger workpieces.

Construction Quality: Strong material to provide strong performance.

Brand + Customer Service: Trustworthy manufacturer, after-sales.

Maintenance Tips

Coat moving parts regularly with lubricant.

Clean the working table and rust. Keep in a dry and clean place.

Check and tighten all bolts and fasteners.

Check drill bits and change accordingly.

Make sure there is a safe electrical connection.

Technical Specification - We Offer This Types of Pillar Drill Machines

20MM Pillar Drill Machine

| Brand | SKI |

| Range of Spindle Speed | 8 |

| Drilling Capacity | 20MM |

| Type | Pillar drill machine |

| Drilling Capacity (Steel) | 20MM |

| Type of Drilling Machine | Pillar |

| Usage/Application | Drilling |

| Table Size | 275mm X 275mm |

| Material | Metal |

40MM Pillar Drill Machine

| 40mm Pillar Drill Machine | |

| Minimum Order Quantity | 1 Piece |

| Type of Drilling Machine | Pillar |

| Drilling Capacity | 40 MM |

| Power | 1.5 H.P. |

| Range of Spindle Speed | 2800 RPM |

| Spindle Travel | 250 |

| Body Material | Metal |

| Base Size | 440 X 715 |

| Table Size | 410 X 410 |

| Distance from Spindle Nose to Pillar Surface | 595 |

| Voltage | 440 V |

| Phase | 3 PHASE |

| Country of Origin | Made in India |

25MM Pillar Drill Machine

Drilling Capacity In Steel | 25 mm |

Spindle Travel | 250 mm |

Taper in Spindle | Mt-3 |

No of Speed | 8 Speed |

Spindle Speed Rang | 70 RPM to 1980 RPM |

Column Diameter | 89 mm |

Center of Spindle to Column | 250 mm |

Max. Dist. of Spindle Nose to Table | 580 mm |

Max. Dist. of Spindle Nose to Base | 990 mm |

Square Working Table Dimension | 340 mm x 340 mm |

Working Table Base is without Tilting | Fix Type |

Overall Base Dimension (L x W) | 625 mm x 420 mm |

Base Dimension (Machined Area) | 325 mm x 315 mm |

Number/ Size of Slot | 2/12 mm |

Drilling Motor | 0.75 KW, 1440 RPM |

Drive | ‘V’ Belt (B-52) |

Overall Dimension ( L x W x H) | 750 mm x 420 mm x 1700 mm |

Weight | 225 Kg (Approx) |

6mm Pillar Drill Machine

Drilling Capacity in Steel | 6 mm |

No.Of Spindle Speed | 5000 to 6000 |

Spindle Nose Taper | jacob 2 (1) taper |

Spindle Center to Column | 153 MM |

Spindle Travel | 65 MM |

Maximum Distance Between Chuck To Table | 135 MM |

Maximum Distance Between Chuck To Base | 360 MM |

Working Surface of Base | 208 x 192 MM |

Working Surface of Table | 210 x 207 MM |

Column Diameter | 47 MM |

Base To Machine | 320 x 235 MM |

Overall Dimensions | 840 x 320 x 560 MM |

Motor Speed | 2800 R.P.M. |

Motor 3 Phase,induction, A.C. | 0.37 KW. / 0.5 HP. |

Weight of Machine (Approx.) | 42 KG |

Get the Best Pillar Drill Machine Price in India

Without compromising quality, we have competitive prices for all models. If you are to require a standard pillar drilling machine for the workshop or a sturdy one for continuous production, we have the ability to give you the right model at the best price.