- SINCE 1965

INDIA'S BRANDED COMPANY FOR PILLAR DRILL MACHINE MANUFACTURER

S.K. Industries has been the leader in the Drill Machine Manufacturer for more than 60 years in Ahmedabad, Gujarat. We are a pioneer and a principal manufacturer of an expansive series of drilling machines, namely pillar drill machine and heavy-duty industrial drilling machines, with an unquestionable resolute dedication to quality. We have a heritage of producing precision, reliability, and 100 % customer satisfaction in India.

We market an extensive assortment of industrial drilling products designed to satisfy the changing requirements of the manufacturing, metalworking, construction, woodworking, and heavy machinery industries.

Our Vision

To elaborate the network by keeping pace with the upcoming technology and make attempts to introduce the best in-class drill machine at the most competitive rates in the industry.

Infrastructure

We have with us fully fledged manufacturing unit spread considerably in the large area that helps us to develop our range of engineering machinery with supreme quality.

Our Mission

To provide revolutionary yet viable solutions to the competitive global marketplace, whilst matchless level of friendly and trustworthy service in a professional manner.

- SINCE 1965

What we offer for you

Leading Pillar Drill Machine Manufacturer in Ahmedabad – Trusted Across India

Heavy Duty Drill Machine

Built for strength and performance, our 40mm heavy duty drill machines are perfect for large-scale industrial drilling applications and rugged use.

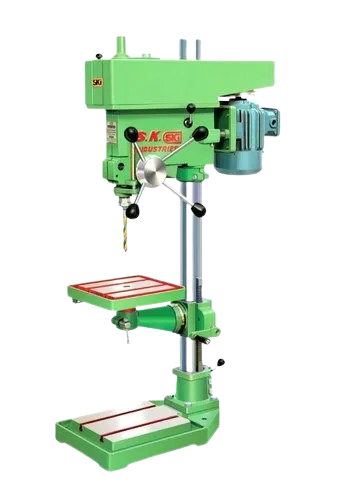

Pillar Drill Machine

Our prominent 25mm, 38mm, and 40mm pillar drill machines are ideal for precise hole-making in metal, wood, and fabrication workshops.

Standard Drill Machine

Compact and versatile, our 13mm and 20mm drill machines are ideal for daily workshop and light-duty manufacturing use.

Key Features Of Drill Machine

High Precision Drilling Capability

Precision of hole drilling is provided by advanced spindles and depth control on a range of materials such as metal, wood, and plastic.

Heavy-Duty Construction

Its good durability, low vibration and prolonged life of machines are because of the strong cast iron or steel body structure and it suits this continuous industrial application.

Variable speed control

The modern drill machine is designed with a mechanical or an inverter-controlled speed control system to optimize drilling of various materials and drilling sizes.

Strong Motor Output

High-performance motors (usually 0.5 HP to 3 HP or more), produce efficient drilling with consistent torque at a variety of speeds.

Optional Automatic Feed Mechanism

More efficient and accurate throughout the drilling process through a consistent pressure and rate of feed, meaning that whatever drilling action is repetitive in nature.

Height Adjustable Table and Swivel

The worktable may move upwards and downwards, and rotate 360 degrees, which makes drilling at different angles and heights quite flexible. Digital RPM and Depth Monitoring (on the high-end models)

Depth Stop / Scale Indicator

Depth gauge built-in enables the user to control the depth of a hole accurately, thus minimizing the wastage of materials and creating a high level of accuracy. Different chuck sizes (e.g., 13mm, 16mm, 20mm, 25mm, etc.).

Safety Features & Spindle Speed Ranges

Provided with emergency stop buttons, overload protection, belt guards and safety switches to eliminate accidents. Provides both huge RPM ranges (e.g., 100 3000 RPM).

Upgrade Your Workshop with Our Heavy-Duty Pillar Drill Machine Supplier in India

We are a branded name in the drilling industry, engaged in offering clients a superior quality Pillar Drill Machine. High-precision pillar boring tools are provided in 2 different hole-making capacities of 6mm, 20mm, 25mm, and 40mm.

Pillar drill machines built today have variable speed controls that enable the user to adjust the spindle speed finely, to match the material and drilling needs. This flexibility causes fewer hiccups during operation and up to 40 percent faster drilling speeds with high accuracy levels. Improved motor technology also provides these higher speeds without compromising precision or tool life.

The use of digital depth indicators is now common on many pillar drill types, allowing correct hole depths to be set with a minimum of guesswork. Pillar drilling Machine has been transformed by the introduction of CNC (Computer Numerical Control) technology, which has automated the drilling of repeatable, high-precision holes. CNC pillar drills have computer programs that allow the control of movement and drilling parameters in order to maintain quality production in different workpieces.

Functions, Uses & Applications of Drill Machine

| Common Use | Application |

| Drilling Holes | Holes made in wood, metal, plastic, and concrete to be assembled or fastened. |

| Tapping | Making internal threads on drilled holes for screws and bolts. |

| Reaming | Expanding and polishing of existing holes. |

| Countersinking/Counterboring | Holes to be prepared with flat-head screws or with (enlarged) openings. |

| Boring | Expanding pre-existing holes of the correct size. |

| Mixing | With attachments, to mix paint, cement, adhesive, etc. |

| Polishing & Buffing | Rotary finishing of metals and wood. |

Looking for high-quality pillar drill machines in your workshop or industry? Our pillar drills are accurate, stable, and ideal in metalworking, woodworking, and construction.

Why Select Our Pillar Drill Machines?

- Drilling accurately: Make the holes all the same and all accurate.

- Stable base and strong column: Heavy-duty construction to ensure long-term operation.

- Flexible Applications: It is suitable for metal, wood, and plastic materials.

- Industrial / Workshop Friendly: Bench or floor models available to meet your requirements.

Our pillar drill machines, whether it be a professional work workshop or an industrial manufacturing unit, are designed to provide an efficient and reliable workforce for all your drilling needs.

Explore Our Full Range →

What Our Happy Clients Say

I had purchased 13mm Capacity Drilling machine before 50 years ago today they repair my Drilling machine. They can supply Spare parts of there company as well. Good machine. I am from meshana. Gujarat.

Bharat PanchalI am naranbhai panchal from naroda, Ahmedabad. I am using SKI Drill machine since more then 50 years. They give us Good and best qualities of Drill machines. 13mm Drill machine are Best. Also they give us spare parts at reasonable price. Thanks to him. My 50 years old machine running nicely.

Narayan PanchalSuper, Good and awesome Drilling Machine. WE ARE USESING SINCE LAST 50 YEARS. PEOPLE ARE ALSO GOOD. NICE RESPONSE.

Sanjay Dabhi- FAQ's For Drill Machine

The drill machine is a piece of equipment utilized to drill round holes in, and to put fasteners through, materials like metal, wood, and plastic.

Sought-after types consist of bench drills, pillar drills, radial drills, cordless drills, and the most recent models, hammer drills.

A bench drill and a pillar drill are the two most different types. A bench drill is an over-the-head hanging drill that can be also called an electric drill and a pillar drill, lathe, mill, or a drill press.

When purchasing a drill machine in 2025 with the core features of motor power, drilling capacity, speed control, build quality, and safety features, the attributes to be expected of a drill machine should be the highest in the following areas.

Traditionally, a small range of drilling materials has been limited to wood, plastic, and metals; nevertheless, modern drills can work on wood, plastic, ceramics, concrete, and even glass with the right bits.

Keep it clean - remove the dirt; keep it lubricated - moving parts to move freely, check for worn-out bits or loose components regularly.

The new features that have come to the market can be no less than those of recent brushes with squirrel-cage technology - the brushless direct-current motor, the torque control system, and a fully monitorable digital speed setting feature.